| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : Lijiang

Model Number : LJLBQJ2500

Certification : CE

Place of Origin : China

MOQ : Negotiable

Price : Negotiable,

Payment Terms : T/T, L/C

Supply Ability : 10set/month

Delivery Time : 20days

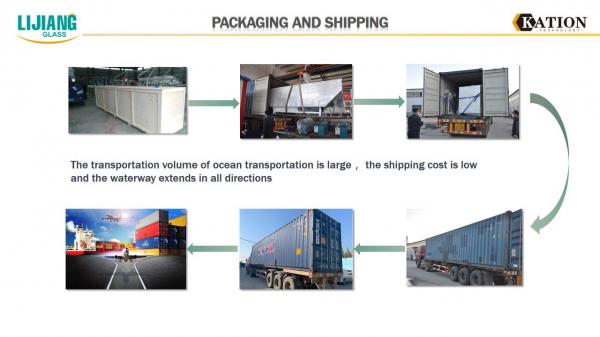

Packaging Details : wooden case or container

Name : Vertical Washing And Drying Machine

Material : Stailess stell touching water part

Advantage : Brush for Low-e

Feature : Easy Opration

Automatic Vertical And Horizontal Washing And Drying Machine Easy Opration Glass Cleaning

LIJIANG GLASS- FOR WORLD GLASS MACHINE USER SERVICE

Glass Washing Machine LJLBQJ2500

►The water tank system and water heating fuction

►Using Europe's advanced anti-noise system to create a good working environment for employees.The noise can be controlled below 90 decibels by using nylon gear and sponges.

Brief introduction of automatic glass cutting table

• Its working principle is to convey the cut glass by conveying belt to worktable, automatically input the position of glass through photoelectric scanning system, and then the cutting head with diamond wheel on the cutter holder moves along X and Y directions respectively by program control,cutc the sheet. CNC motion controller is used in the control part of the machine, and advanced AC servo motor is used in the drive part.

|

|

|

|

• ,Max size:6100×3300mm • ,Thickness:3~19mm • ,Cutting accuracy:±0.30 • ,Cutting accuracy of special-shaped glass:±0.35 • ,Cutting speed:0-200m/min • ,Conveying speed:0-25m/min • ,Machine size:6800×4100×1500mm • ,Working table height:900mm±20mm • ,Weight:2600kg • ,Total power of equipment:9-15kw |

Motion Controller:

• 1) Fast running speed, smooth running, high control accuracy, modular controller structure;

• 2) The man-machine interface is simple and generous, the parameter adjustment is simple, the parameters that need to be modified by operators are less, simple and intuitive, and the requirements for operators are low.

• 3) Pipeline cutting mode, photoelectric positioning cutting mode and direct cutting mode are set freely through options. The automatic cutting mode and air operation mode can be switched at any time during the processing.

• 4) Graphic library nesting programming, select special-shaped from the library, set relevant parameters, processing quantity, automatic nesting, generating processing trajectory;

• 5) Complete storage of glass pressure stock, once the cutting pressure of each specification thickness is input and saved, it can be directly invoked;

• 6) Real-time tracking and displaying of processing path, timely recording of motion coordinates, axis state, I/0 state, automatic recording of fault diagnosis and alarm;

• 7) Receive a variety of processing documents, accept the standard G code of Optima, Super Package Software, AUTOCAD DXF file, the system has its own graphics editing software (exactly the same as Paul's editing method);

• 8) Graphic library nesting programming, selecting abnormal shape from the library, setting relevant parameters, processing quantity, automatic nesting, generating processing trajectory;

• 9) The sorting function of DXF class files, including the nearest point, entry point, or by graphics color clockwise, counterclockwise sorting and other options. Free the switch between single-phase cutting and bidirectional cutting is realized.

• 10) Photoelectric positioning function, according to the actual position and deflection angle, automatically adjust cutting;

• 11) Compensation function: tool eccentricity compensation, clearance compensation, pitch compensation;

• 12) All kinds of protection: including soft and hard limit, cutter pressure limit, external emergency stop control and so on.

Optimization software:

• ,Importable optimization results done in the Office

• ,Cutting scheme can be manually created and edited

• ,With copy and mobile functions

• ,Manual editing of cutting sequence

• ,The cutting scheme can be quickly created by X, Y and Z modes.

• ,Simultaneous optimization of multiple original and small patches

• ,Optimized typesetting without size limitation

• ,Optimized Result Rotation, Mirror Management, etc.

• ,Priority management for small size cutting optimization

• ,Priority management of original glass sheet optimization

• ,Template Scanning Function and Scanning Graphics Processing

• ,Original glass sheet storage Management

• ,20 efficient optimization algorithms

• ,Cutting graphics can be edited

• ,Label Design and Label Printing(Label-WAY)

• ,Clear Printing of Optimized Result Report

• ,Excel Data File Import

• ,Low-E and Adhesive Glass Cutting Management

• ,A graphics library containing 350 parametric graphics, including all the commonly used graphics types (Geo-Way)

• ,Two-Dimensional CAD System with Abnormal Scanning Processing Function (Cad-Way)

• ,Automatically converting digital signals from CNC systems into graphical forming points

• ,There are many language choices for the software operation interface, including the Chinese interface.

• ,Follow up the latest international software development, provide upgraded versions in real time, and achieve the latest functional requirements for customers

|

|

Automatic Vertical Glass Washer and CNC automatic glass cutting Table 6033 Images |