| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : Lijiang

Model Number : LJBZ2025

Certification : CE

Place of Origin : China

MOQ : 1set

Price : Negotiable,

Payment Terms : L/C, T/T

Supply Ability : 10set/month

Delivery Time : 60days

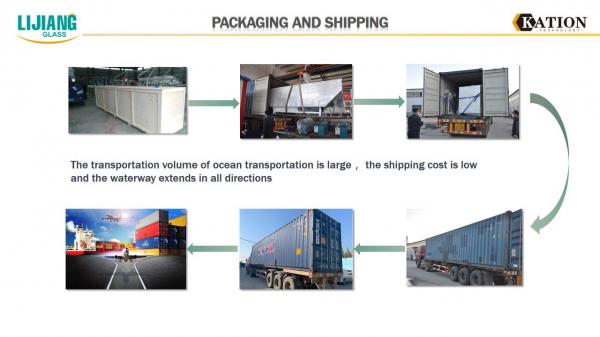

Packaging Details : wooden case or container

Name : Insulating glass processing line

PLC : Siemens

Advantage : gas filling on line

Automatic Vertical Insulating Glass Processing line LJBZ2025

LIJIANG GLASS- FOR WORLD GLASS MANUFACTURE SERVICE

LJBZ2030Vertical Automatic Insulating glass production line

APPLICATION

As the most important process of insulating glass production, we are especially professional in glass cleaning, transmitting pressing and gas filling(optional).The production line can do double glass,triple glass and stepped glass.

LJBZ2025 Vertical Automatic Insulating glass production line include 7 parts: (standard model :from right to left)

The whole line include 7 parts: (from right to left)

1,Loading section(with low-e checking)

2,washing and drying section(can washing low-e glass)

3,conveyor section

4,checking and assembly section

5, conveyor , measure and sensor section

6,press part with gas filling

7,unloading section

►SIEMENS CONTROL SYSTEM

►SIEMENS CONTROL SYSTEM

►ROLLERS SHOWING

►ROLLERS SHOWING

►WATER TANKER SHOWING

►WATER TANKER SHOWING

1,Loading section(with low-e checking)

2,washing and drying section(can washing low-e glass)

3,conveyor section

4,checking and assembly section

5, conveyor , measure and sensor section

6,press part with gas filling

7,unloading sectionSemi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine Advantage:

Parts list

| Components | Brand | Remark |

| Servo motor | GERMAN SIEMENS | For stepped glass |

| Servo driver | GERMAN SIEMENS | For stepped glass |

| Servo motor | GERMAN SIEMENS | For transfer |

| Servo motor | GERMAN SIEMENS | For press |

| PLC | GERMAN SIEMENS | |

| Low voltage component | GERMAN SIEMENS | |

| Frequency converter | GERMAN SIEMENS | |

| Switching power supply | Taiwan MW | |

| Optoelectronic switch | Korea Autonics | |

| Pneumatic component | Taiwan Airtac | |

| Pneumatic component | Japan SMC | |

| Touch screen | Taiwan Wenview | |

| Travel switch | Taiwan Tiande | |

Main technical parameters

| Max.glass size | 2000*2500mm Gas filling line 2025 |

| Min.glass size | 280*450mm |

| Glass thickness | 3-12mm |

| Insulating glass thickness | 60mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed: | 48m/min |

| Washing brushes | 3 pairs |

| Water supply: | Water consumption:0.5t/h conductivity:≤50μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P380V 50HZ 34KW |

| Dimension | 23500*3500*3700mm |

Cantilever crane LJXJ500-800

1. This vacuum glass lifter is for handling insulating glass sheet.

2. This glass lifter is able to lift the glass sheet with 800kg

3. It is equip with 5 suckers. But the sucker can be add according to need of the client.

4. The equipment is Stable, Easy to use and safe.

5. The vacuum lifter is equipped with a warning light in case of a power failure or vacuum leakage, an optical and an acoustic signal goes off immediately to warn the operator to do emergency operation.

Parameter:

| Safety-absorption | 200KG/400kg/600kg/800kg |

| Performance | Rotation 0-90 degree and lifting 600-1200mm |

| Quantity and size of sucker | 2/4/6/8 |

| Working gas source | 5-8 Pa |

| Outer size | L 1120xW660XH620mm |

| Net weight | 550kg |

|

|

PLC Control Vertical 7 Parts Insulating Glass Processing Line Images |